HDPE Liner

HDPE liners, made from High-Density Polyethylene, are renowned for their durability and chemical resistance. They are commonly used in landfill containment, mining, and water treatment applications to prevent contamination. These liners are UV-stabilized, making them suitable for long-term outdoor use. Their flexibility allows them to conform to uneven surfaces, ensuring a secure fit. Installation involves heat-welding seams for a leak-proof barrier. HDPE liners are resistant to harsh chemicals, including acids and alkalis. They are also recyclable, contributing to environmental sustainability. The liners come in various thicknesses, offering options for different levels of protection. Additionally, they require minimal maintenance, with easy repairs if necessary. HDPE liners play a crucial role in protecting soil and groundwater from pollution.

Benefits:

-

- HDPE liners create a water-proof barrier, reducing water loss due to seepage.

- Helps conserve water assets and preserve constant water degrees.

-

- Prevents the change of water and pathogens among the pond and the encompassing soil.

- Reduces the risk of infection and disorder outbreaks.

-

- Smooth surfaces prevent sludge and organic waste accumulation, simplifying pond cleansing.

- Enhances water great and decreases labor charges.

-

- Maintains better water parameters by way of minimizing sediment interactions.

- Provides a clean and controlled environment, which supports healthful shrimp and fish growth.

-

- Resistant to UV radiation, chemicals, and intense weather situations, ensuring long carrier lifestyles.

- Suitable for both freshwater and saline environments.

-

- Reduces maintenance and restore fees as compared to standard earthen ponds.

-

- Increases productiveness with the aid of minimizing environmental and control dangers.

Specifications:

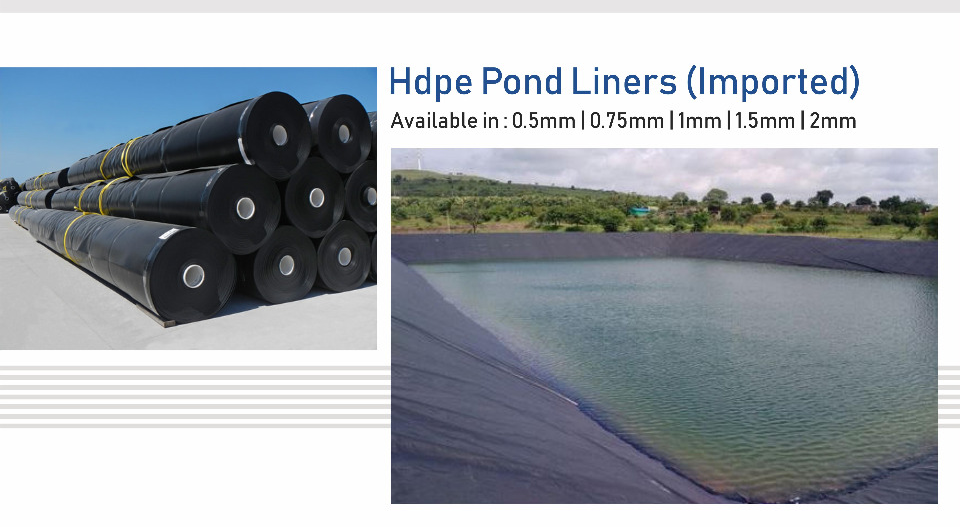

- Thickness:

- Typically ranges from 0.5mm to 2.00mm.

- Thicker liners are more durable and resistant to punctures, ideal for intensive farming.

- UV Resistance:

- Liners should be UV-stabilized to withstand prolonged sun exposure without degradation.

- Chemical Resistance:

- Resistant to acids, alkalis, and salts, making them suitable for saline or brackish water ponds.

- Flexibility:

- HDPE liners are flexible, allowing them to adapt to pond shapes and sizes.

Installation:

1.Site Preparation:

- Clear the pond area of debris, sharp objects, and vegetation.

- Level the pond bottom and sides to avoid stress points on the liner.

2.Proper Laying:

- Lay the liner smoothly without wrinkles or folds.

- Allow some overlap between liner sheets for secure seaming.

3.Seaming and Welding:

- Use hot wedge welding or extrusion welding to join the liner seams for a waterproof seal.

- Inspect seams for leaks using air pressure or water testing.

4.Anchoring:

- Secure the edges of the liner in an anchor trench around the pond to prevent movement.

5.Protection:

- Use geotextile fabric beneath the liner for added protection against punctures.

- Cover exposed areas with soil, sand, or water to reduce UV exposure.

Maintenance Tips:

- Regular Inspections:

- Check for tears, punctures, or leaks and repair them promptly.

- Avoid Sharp Tools:

- Use non-sharp instruments during pond cleaning to prevent accidental damage.

- Control Predator Damage:

- Protect against burrowing animals or sharp objects from outside the pond.

Advantages:

- Enhances pond management efficiency and biosecurity.

- Promotes higher stocking densities and yields.

- Reduces water and soil contamination, fostering better shrimp health.

- Provides long-term cost savings through reduced maintenance and improved productivity.